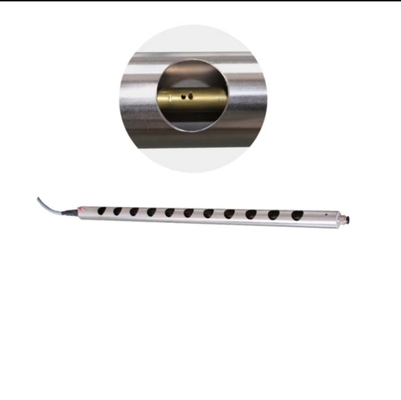

Static Discharge Ionizing Bar Static Elimination Bars

Product Details:

| Place of Origin: | SH,CN |

| Model Number: | SL-040 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5 sets |

|---|---|

| Price: | 80USD-120USD/set |

| Delivery Time: | 2-5 workdays |

|

Detail Information |

|||

| Operating Voltage: | 7000V/50Hz Or 7000V/60Hz | Current Consumption: | 0.4uA |

|---|---|---|---|

| Operating Temperature: | 22-25℃ | Working Distance: | 100mm(without Compressed Air) 800mm(with Compressed Air) |

| Model: | ST-040 | Compressed-air Pressure: | 5~7Kg/cm2 |

| Highlight: | static elimination ionizing bar,ESD static discharge bar,ionizing bar for static control |

||

Product Description

| Distance | Elimination Time: | |

| Without Compressed Air |

With Compressed Air |

|

| 20mm | 0.3s | 0.1s |

| 40mm | 0.3s | 0.2s |

| 60mm | 0.5s | 0.3s |

| 80mm | 1.95s | 0.4s |

| 100mm | 1.5s | 0.6s |

| 300mm | - | 1.3s |

| 600mm | - | 2.5 s |

| Testing Voltage:5KV to 500V | ||

Anti Static Ionizing Bar Static Eliminator Rod

Anti Static Rod

Especially suitable for large, whole and small mechanical equipment, easy to install.

Applications:

Suitable for precision electronic products, electronic assembly lines, pharmaceutical assembly lines, printing and packaging, shaping small products, it is an ideal professional equipment for removing static and dust.

Benefits:

1. Quickly neutralizes static electricity.

2. Stable and safe working performance;

Please contact us to customize the ioning bar length.

Product Application / Use:

This high-efficiency ionizing bar with a high-voltage power supply is designed to eliminate static electricity in a wide range of industrial applications.

It is especially suitable for:

-

Printing facilities – Prevents paper misfeeds, ink splashes, and dust attraction during high-speed printing.

-

PCB assembly workstations – Eliminates electrostatic discharge (ESD) that can damage sensitive components during electronics production.

-

Plastic film and sheet production – Removes static from surfaces during extrusion, cutting, or rolling to ensure smooth processing.

-

Packaging lines – Prevents static-related issues like film clinging or inaccurate labeling.

-

Textile and nonwoven manufacturing – Reduces static buildup that may cause tangling, attraction of dust, or machine malfunction.

-

Conveyor and automation systems – Neutralizes static to ensure stable operation and material handling.

By continuously releasing ions, the system effectively neutralizes static charges on charged surfaces, improving product quality, reducing downtime, and enhancing operator safety.