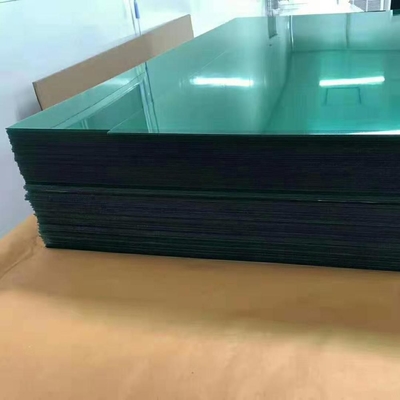

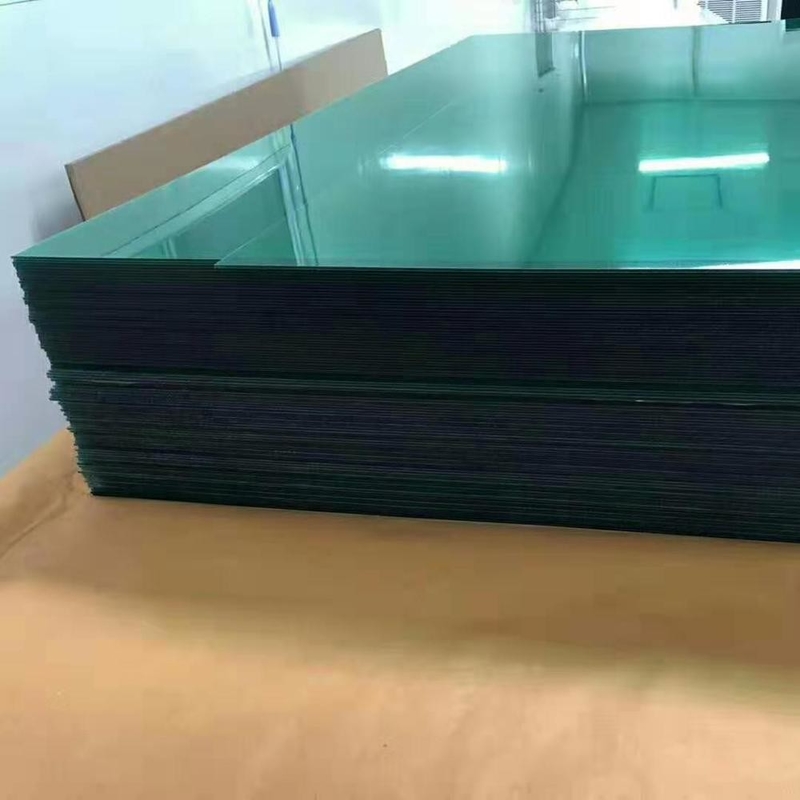

Antistatic Permanent ESD PC Sheet Colored Esd Plexiglass Acrylic Sheet

Product Details:

| Place of Origin: | SHN |

| Brand Name: | Herzesd |

| Certification: | CE, ROHS |

| Model Number: | Acrylic |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000kg |

|---|---|

| Price: | 2-5 / kg |

| Packaging Details: | Carton with pallet |

| Payment Terms: | Western Union, MoneyGram |

| Supply Ability: | 1000 Ton per Week |

|

Detail Information |

|||

| Material: | Acrylic | Thickness: | 0.8-50mm, 2-20mm |

|---|---|---|---|

| Size: | 1220*2440mm(4*8foot), 1*2M; 1.22*2.44M Customized | Processing Service: | Cutting, Colored |

| Color: | Transparent; Half Transparent With Color Can Be Customized | Feature: | Permanent ESD, Anti-UV, Flame Retardant |

| Usage: | Acrylic Products | Packing: | Wooden Box |

| Port: | Shanghai | ||

| Highlight: | permanent ESD PC Sheet,Antistatic permanent ESD PC Sheet,50mm esd polycarbonate sheet |

||

Product Description

With anti-static acrylic sheeting, you can stop worrying about electrostatic discharge causing latent damage and rejects to electronic items. Also known as electrostatic dissipative (ESD) acrylic, the anti-static acrylic sheeting is coated with a transparent material that prevents the formation of static electricity on the surface. Because the coating offers a permanent solution, ESD acrylic is not affected by humidity like topical, temporary anti-static coatings used on traditional plexiglass. Antistatic acrylic sheeting has incredible strength and resistance to abrasions and chemicals, and can be fabricated into a wide array of shapes and sizes.

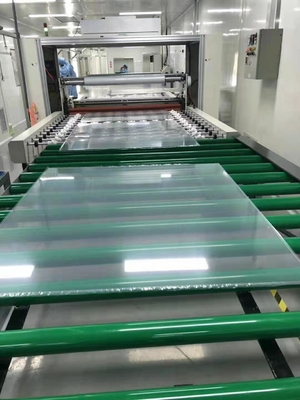

Antistatic ESD acrylic is ideal for any applications involving electricity or electrically conductive surfaces including static control shields, glove boxes, conveyor line covers, electronic equipment and more.

| Item no. | Model | Thickness (mm) | Specification (mm) | Basic performance | ||||||||||||||

| Gravity | Transmittance (%) |

Haze (%) |

Fracture tensile strength (MPa) |

Adjustable rate(%) | Elastic ratio (MPa) |

Shock resistance (KJ/m2) |

Rockwell hardness | Thermal deformati on(℃) | Thermal expansivity (/℃) |

Water absorption | Pencil hardness | Steel wool test | Inflammablity | Flame retardant rating | ||||

| ASTM D792 | ASTM D1003 | ASTM D1003 | ASTM D638 | ASTM D638 | ASTM D790 | ASTM D256 | ASTM D785 | ASTM D648 | ASTM D696 | ASTM D570 | ASTM D3363 | 0000#,500g, 500times |

ASTM D635 | UL-94 | ||||

| Anti static PVC Plate | FD01-CR00 | 5 | 1200× 2400 | 1.38 | 73 | 3 | 50 | 7 | 80 | 2.3 | 76 | 65 | 6.7×10-5 | 0.2 | HB | Scratched | Self-extinguishing | V-0 |

| 1000× 2000 | ||||||||||||||||||

| FD01-CR02 | 5 | 1200× 2400 | 1.38 | 75 | 3 | 50 | 7 | 80 | 2.3 | 76 | 65 | 6.7×10-5 | 0.2 | HB | Scratched | Self-extinguishing | V-0 | |

| 1000× 2000 | ||||||||||||||||||

| FD01-YW00 | 5 | 1200× 2400 | 1.38 | 70 | 3 | 50 | 7 | 80 | 2.3 | 76 | 65 | 6.7×10-5 | 0.2 | HB | Scratched | Self-extinguishing | V-0 | |

| 1000× 2000 | ||||||||||||||||||

| Anti static PMMA Plate | FD02-CR00 | 5 | 1200× 2400 | 1.2 | 90 | 0.4 | 70 | 2.5 | 90 | 1.6 | 100 | 95 | 6.0×10-5 | 0.3 | 4H | No Scratched | Flammable | HB |

| 1000× 2000 | ||||||||||||||||||

| Anti static PC Plate | FD03-CR00 | 5 | 1200× 2400 | 1.2 | 85 | 0.9 | 71 | 115 | 88 | 13 | 76 | 127 | 5.2×10-5 | 0.15 | HB | Slightly Scratched | Self-extinguishing | V-2 |

| 1000× 2000 | ||||||||||||||||||

| Marks: | ||||||||||||||||||

| Configuration | Article | Test methold | Test condition | Unit | FD01-CR00 |

| Electrical performance | Surface resistivity /sur | ASTM D257 | / | Ohm/sq | 106-108 |

| Friction voltage | SJ/T 10694 | 22℃,50%RH | V | 30 | |

| Static exhausted | GJB 3007A | / | s | 0.2 | |

| Chemical resistance | IPA soak | ASTM D543-14 | After 800h | / | OK |

| IPA scrub | ASTM D543-14 | 500g | times | >2000 | |

| Adhesion | ASTM D3002 | Cross cut test | 100/100 | ||

| Weather resistance | Damp heat test | Damp heat test instrument |

85℃,85%RH,72h | / | OK |

| Salt spray test | GBT-2423 | Neutral salt spray test,80h | / | OK | |

| Boiled | Water bath test | 90℃,2h | / | OK | |

| Thermal performance | Heat cycle | / | (60℃×6h)×10cycles | / | OK |

| Process | Cutting performance | / | / | / | S’ |

| Adaptation | / | / | / | Inadaptation | |

| Bending performance | / | / | / | Bending not available |

![]()

![]()

![]()

![]()

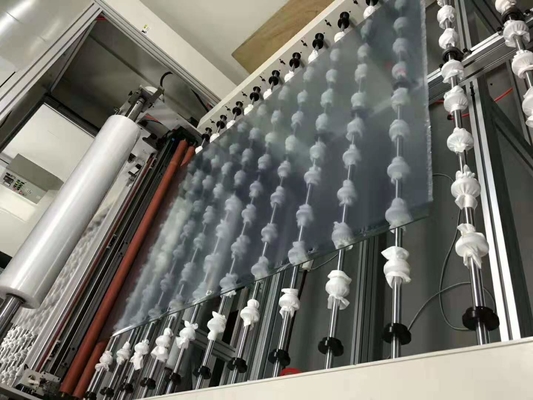

The ESD products manufactured and supplied by Shanghai Herzesd Industrial are the result of meticulous planning and technological excellence. Our products showcase a fine amalgamation of excellence, quality, innovation, and technology. A continuous upgradation is always at place to enhance the security features applicable at various stages and premises on ESD accessories. These products are long lasting and equipped with precision technology. We have a group of hard working personnel who keep detecting the machines for better security.

![]()