Antistatic PVC Floor Tiles Conductive Vinyl Flooring ESD And Antistatic Solution

Product Details:

| Place of Origin: | SH,CN |

| Brand Name: | None |

| Certification: | Rohs, CE |

| Model Number: | HZ-F01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100sqm |

|---|---|

| Price: | 6usd/m2 |

| Packaging Details: | pallet |

| Delivery Time: | 5-7 work days |

| Payment Terms: | T/T, D/P, |

|

Detail Information |

|||

| Color: | Multi Pattern&Color | Thickness: | 2mm/3mm Or 2.5mm |

|---|---|---|---|

| Material: | PVC, Plasticizers, Stabilizers, Etc.. | Surface: | PUR Treatment |

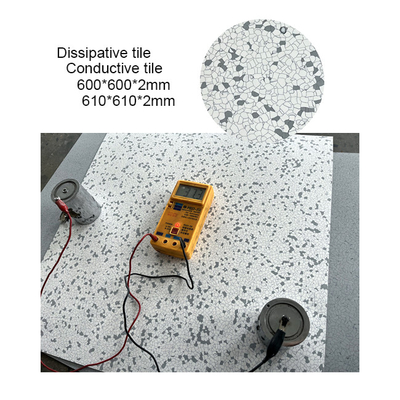

| Product Name: | Conductive Floor Tiles | Surface Resistance: | 10^4-10^6 Ohm/10^6-10^9 Ohm |

| Usage: | Antistatic,Cleanroom Protection | Feature: | Anti-static,Acid And Alkali Resisitant,Oil Resisitant,waterproof,wearable |

| Size: | 10m,or Customized/ 60*60cm & 90*90cm | ||

| Highlight: | Conductive Vinyl Flooring,Antistatic PVC Floor Tiles,ESD PVC Floor Tiles |

||

Product Description

![]()

![]()

The anti-static pvc floor is made up of various materials, including carbon fibers, which will pass the electrostatic charge to the Floor to reduce the risk of a static discharge from physical contact.

It is used to shield devices and other objects from damage caused by static electricity accumulated in the workplace.

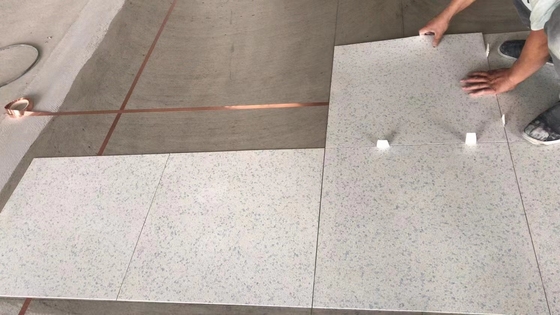

Sheet size: 600mm*600mm/900mm*900mm

Roll size: 2m*20m/Roll

Thickness: 2.0mm/3.0mm (2.5mm customized)

![]()

![]()

![]()

![]()

![]()

PVC flooring features two main characteristics: stain resistance and easy cleaning.

Stain resistance is achieved through seamless interlocking and PUR surface treatment.

Various stains on PVC flooring do not penetrate the floor, preventing dirt residue and odors.

| Item | Standard | Index |

| Size | EN426 | 600*600mm |

| 900*900mm | ||

| Thickness | EN428 | 2.0, 2.5, 3.0mm |

| Weight | EN430 | 2.0mm, 3.8kgs/m3 |

| 2.5mm, 4.8/kgs/m3 | ||

| 3.0mm, 5.8/kgs/m3 | ||

| Surface Rresistance | DIN51953 | 104-106 Ω Conductive |

| ASTMF-1550 or NFPA99 | 106-109 Ω Dissipative | |

| Decay Time | SJ/T10694-2006(VI<100V) | Equal 0.4S |

| Charge Voltage | SJ/T10694-2006(VI<100V) | Equal 70 |

| Fire Resistance | DIN 4102 | B1 |

| Combustion Properties | SJ/T11236-2001(<10s,FV-0) | Equal 0.35s Ifv-0 |

| Amount of anti-wear | SJ/T11236-2001(less than 0.02g/cm3, 110r) | Equal 0.014 |

| Anti-wear Properties | EN660pt2 | Ten-T < 2.0 mm3 |

| Wheel Pressure | EN425 | No influence |

| Residual Concavity | EN433, DIN51955 | 0.03mm(2.0mm) |

| 0.035mm(2.5mm) | ||

| 0.04mm(3mm) | ||

| Dimensional stability | EN434 | Less than 0.1% |

| Color fastness | IDO105BO2 | At least 6 |

| Resistance to chenmicals | DIN423,DIN51958 | offers excellent resistance ask for special sheet |

![]()